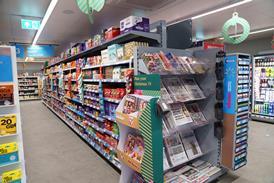

How chillers with doors boosted sales and slashed our energy bill

By Sarah Britton2023-04-18T15:22:00

Sue and Nithy Nithyanandan have cut energy costs by 15%

ALREADY HAVE A REGISTERED USER ACCOUNT? PLEASE LOG IN HERE

To read the full story join the ConvenienceStore.co.uk community today!

Registration is quick and easy and provides access to:

- Unlimited ConvenienceStore.co.uk articles

- Our great range of newsletters

- Content you’ve saved for later via the ‘my library’ feature

And much more…

Related articles

More from Community

Unlimited Access + Newsletters

Register today to gain unlimited access to articles and to receive our great range of email newsletters.