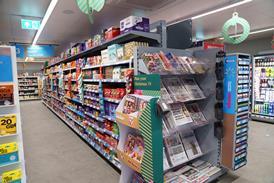

Costcutter retailers near the end of their patience

As the fallout from the switch to the new Costcutter buy and supply system continues, members are becoming increasingly impatient with the ongoing issues, despite signs of improvement in recent weeks.

ALREADY HAVE A REGISTERED USER ACCOUNT? PLEASE LOG IN HERE

To read the full story join the ConvenienceStore.co.uk community today!

Registration is quick and easy and provides access to:

- Unlimited ConvenienceStore.co.uk articles

- Our great range of newsletters

- Content you’ve saved for later via the ‘my library’ feature

And much more…